Description

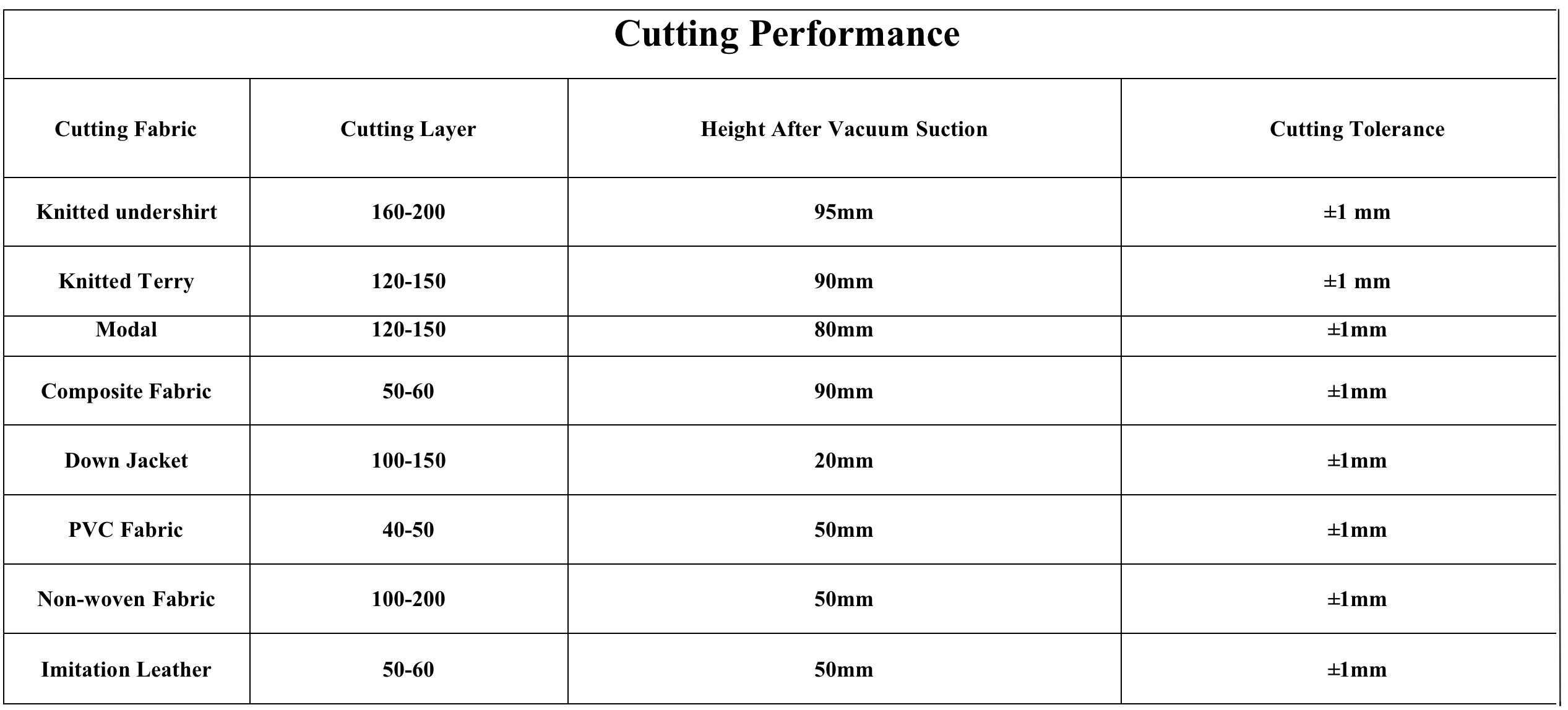

Below Fabric Cutting Layers Is For Your Reference Only, For Some Hard With More Glue Fabric May Need Customize Special Blade And Machine Head.

JDBLTECH Company Vietnam Market Plz Contact :

Mr Toan Zalo: 0912510877( North of Vietnam)

Mr Mathew Zalo: 0978546334( Middle and South of Vietnam)

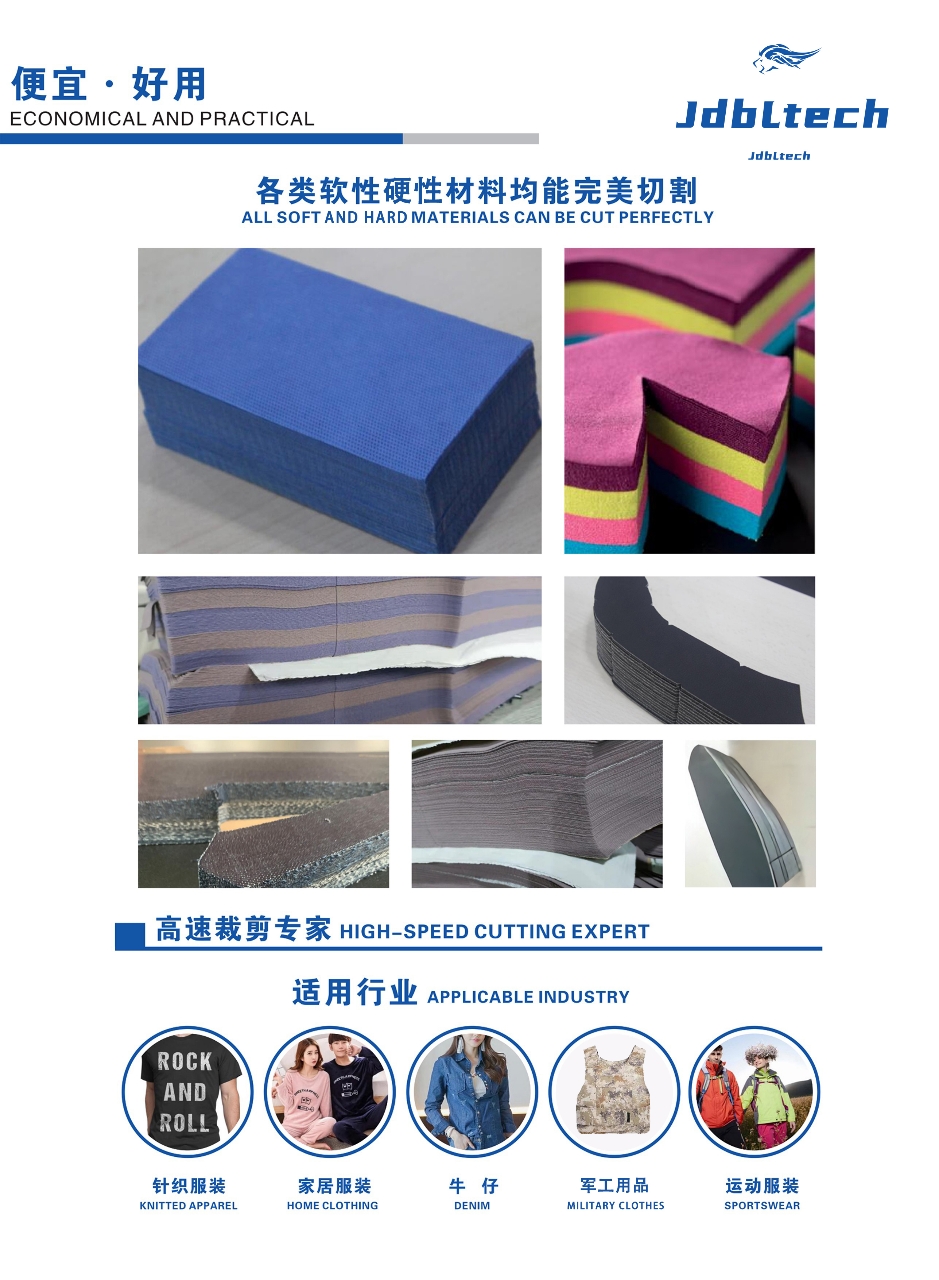

Technical Features:

● Precision cutting velocity control ensures clean cuts on non-breathable and adhesive fabrics

● Web spreading assistance minimizes manual intervention

● Multi-CAD format compatibility for seamless data integration

● Dual-stage vacuum decompression system: noise/dust reduction, temperature control, and eco-compliance (traditional indoor/outdoor exhaust systems fail environmental standards)

● Frequency-conversion controlled energy-efficient pump: noise reduction & power savings

● Streamlined industrial design for ergonomic material handling

● Accessible dust collection window for efficient maintenance

● Simplified structural design reduces consumables costs

● On-screen smart assistant guides operations

● Proprietary motion algorithms enable precision cutting of linear/curved contours

● Automated storage of cutting parameters

● Unlimited cyclic bed replacement capability

● Servo-controlled positioning system ensures precise and stable equipment movement

● I-beam track design prevents derailment in mobile components

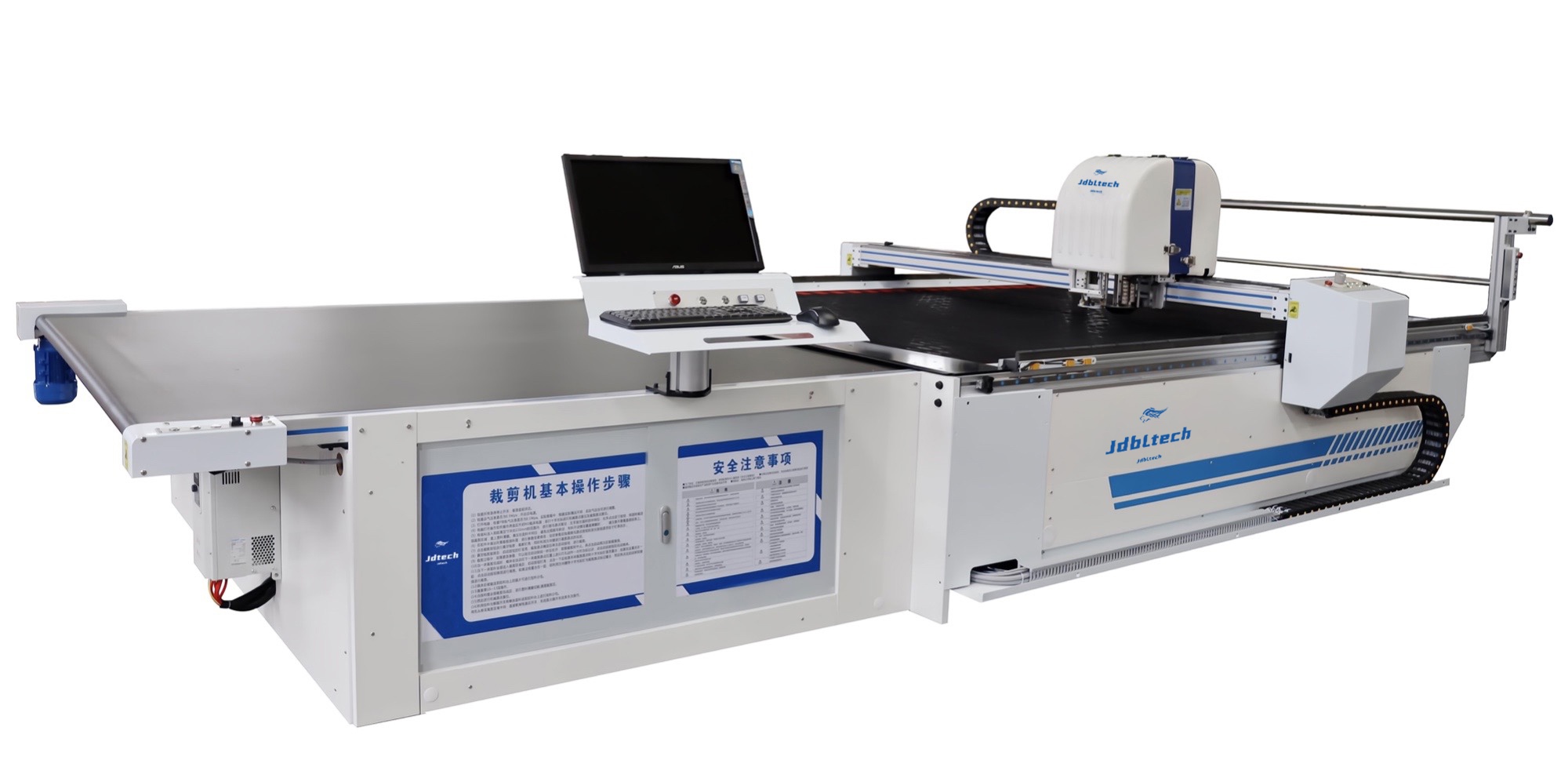

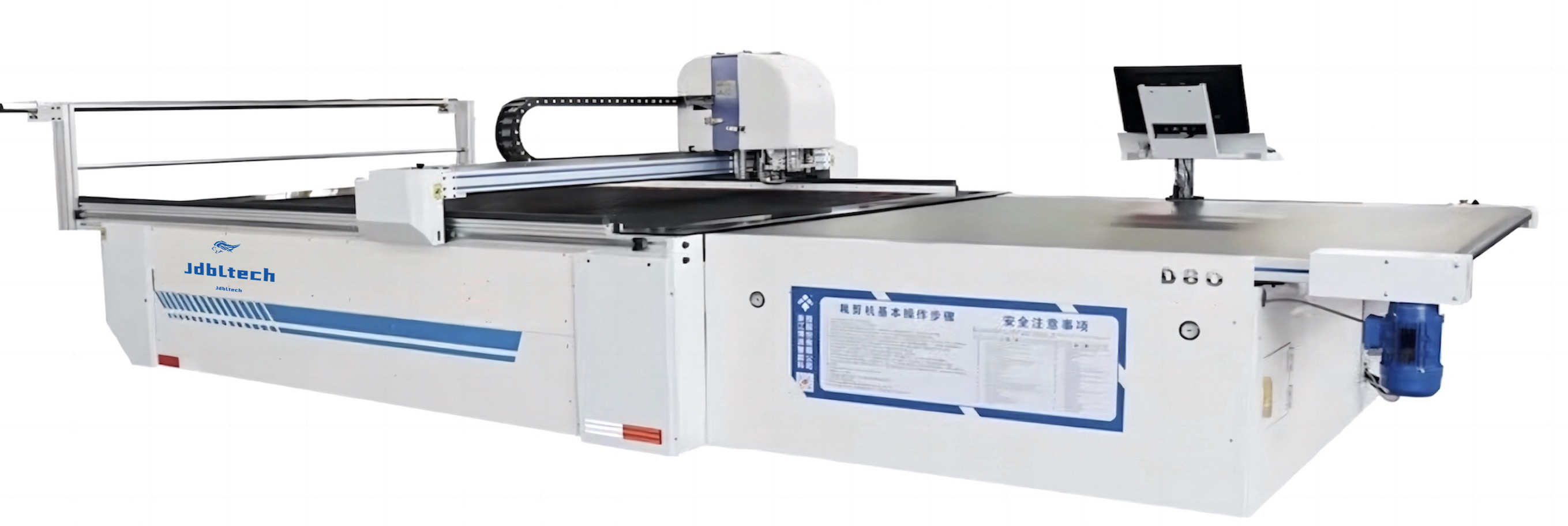

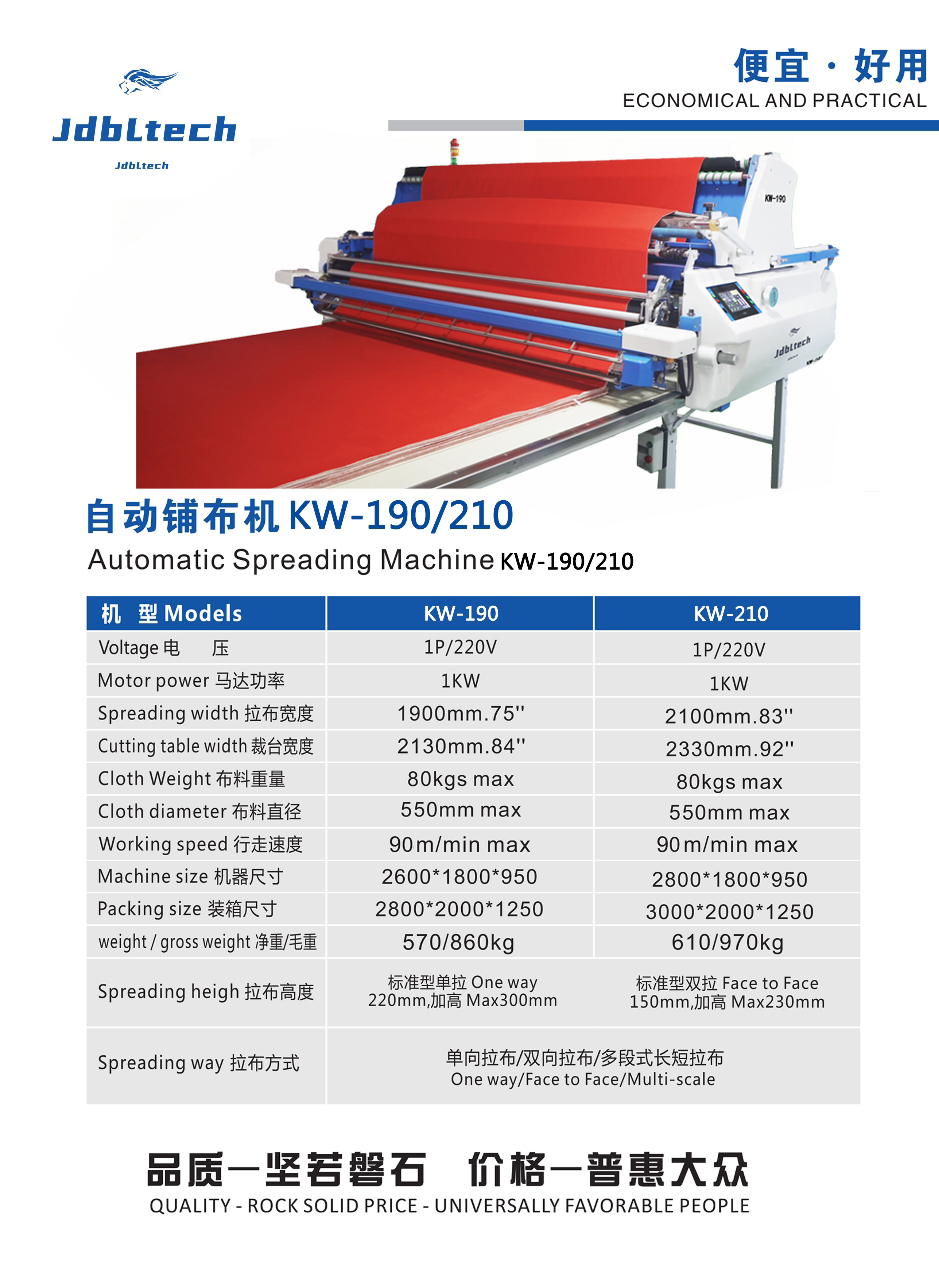

D8002S fully automatic fabric cutting machine is a popular model among middle and small type garment enterprise as for its high performance and affordable price. It has automatic bed change, first-level transmission, automatic knife sharpening, punching device, machine movement, floating knife ,cooling system ,safety device, air condition system, automatic lubrication, dust collection system and so on. cutting area can be 2500mmx2030mm, suitable for most woven and knitting fabric .

Note: The usage cost of Auto Cutter is higher compare to other garment machine, So kindly discuss your production process with sales to judge the cutting blade using frequency per month, and some accessories on the cutting head. Kindly knowing more optional parts from our salesman is helpful to obtain the highest production efficiency , do not waste unnecessary money , keep a good communication with our company rich experienced sales, you are able to choose the appropriate auto cutter. All product specifications and appearances in this catalogue may have been modified. Therefore, the pictures shown may vary. For more details, please contact us.

The software and hardware that may need to be prepared by buyer :

Hardware:

a) Power Line : 4-core 25 square mm; (Length depends on site location)

b) Air pipe: outer diameter 12MM inner diameter 8MM, pressure 0.5MPa (length according to the site location);

c) Air compressor: power 1.5KW above, with filter (filter oil, water, dust, keep dry);

d) Forklift: 5 tons long arm. (The cutting machine installed in the upstairs to have 20 tons of crane, arm length according to the height of the building);

e) Extra voltage stabilizer : May need extra 30KWA output and input 380v /50hz Voltage stabilizer if your factory voltage is waving much often.

f) The floor bearing capacity of the equipment installed by Party A shall not be less than 300kg per square meter.

e) buyer fabric specification to seller

Software:

a)Professional Garment CAD design software , its very normal in local market.

We Factory Production Image:

Packing And Shipping Image: Use iron stand weld before packing with wooden case , 100% prevent the shipping damage for long term shipment .

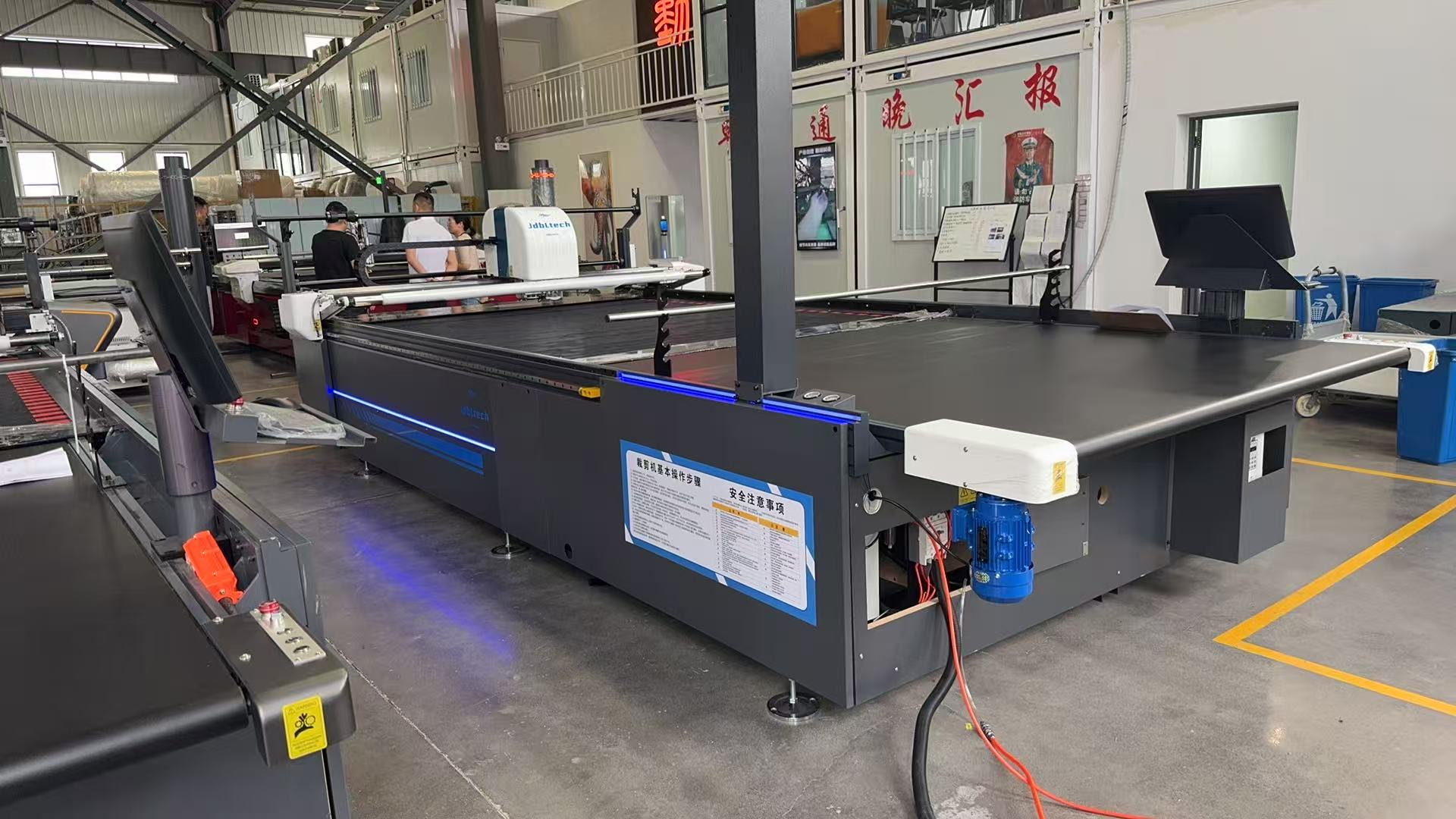

Customer Garment Factory Installation image:

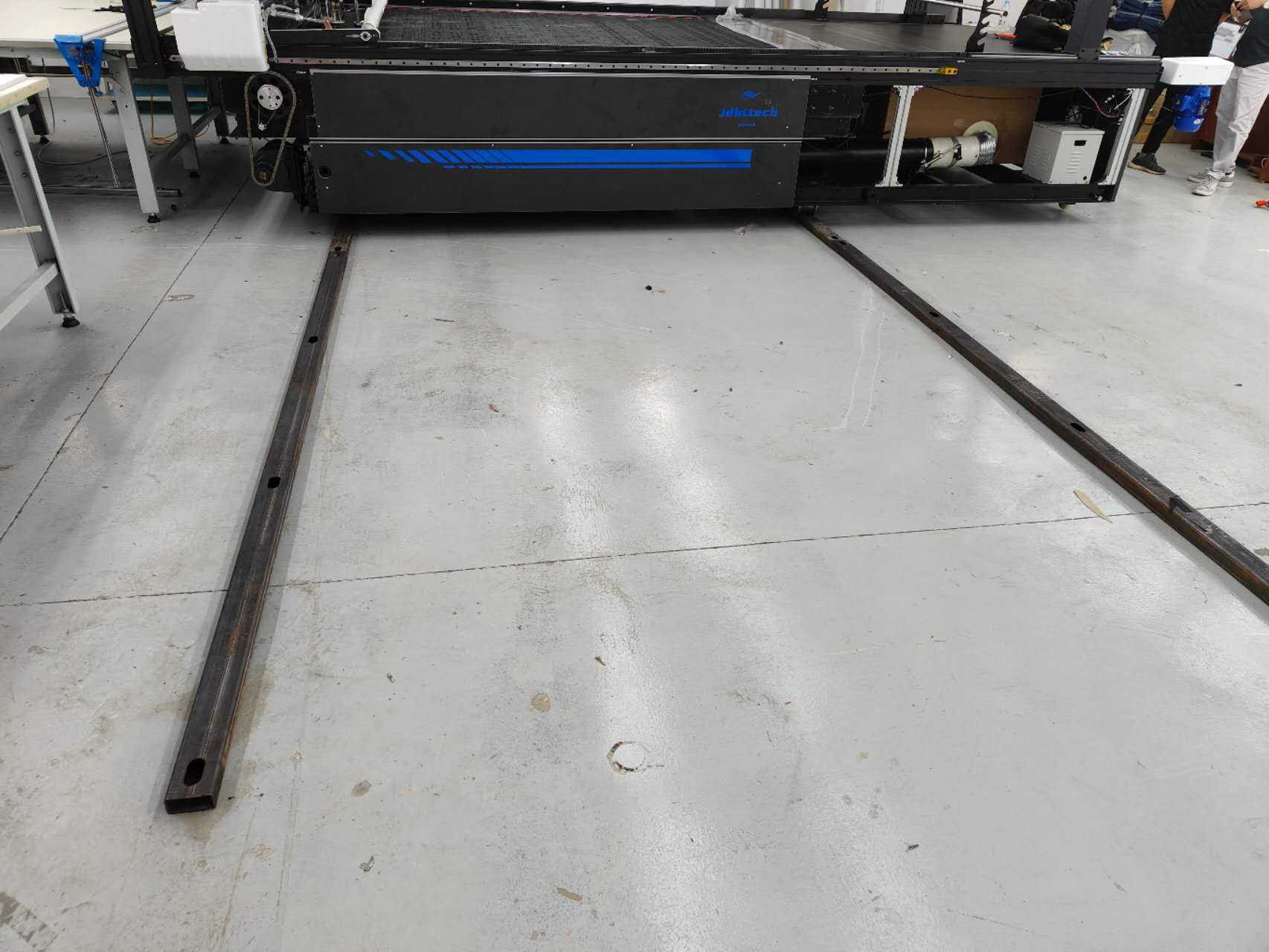

1 Set Automatic Fabric Computer Cutting Machine Match 2 Sets KWS -190 Fabric Spreading Machine With Ground Rail +Top Rail

Installation Details image : fabric cutting machine double blade plate + Air Cool + Oil Cool System

Customer Factory Cutting Performance Image for knitting Fabric :

The seller shall provide permanent online installation and maintenance guidance services. If the buyer needs the seller's on-site installation and training and maintenance, the buyer shall be responsible for the seller's staff's visa, round-trip air tickets, labor cost( if exceed 10 free working days ,we may need charge service fees ,calculating from the first installation day ),accommodation in the destination country, transportation and safety, and arrange local staff to cooperate with the installation.

JDBLTECH Company Vietnam Market Plz Contact :

Mr Toan Zalo: 0912510877( North of Vietnam)

Mr Mathew Zalo: 0978546334( Middle and South of Vietnam)